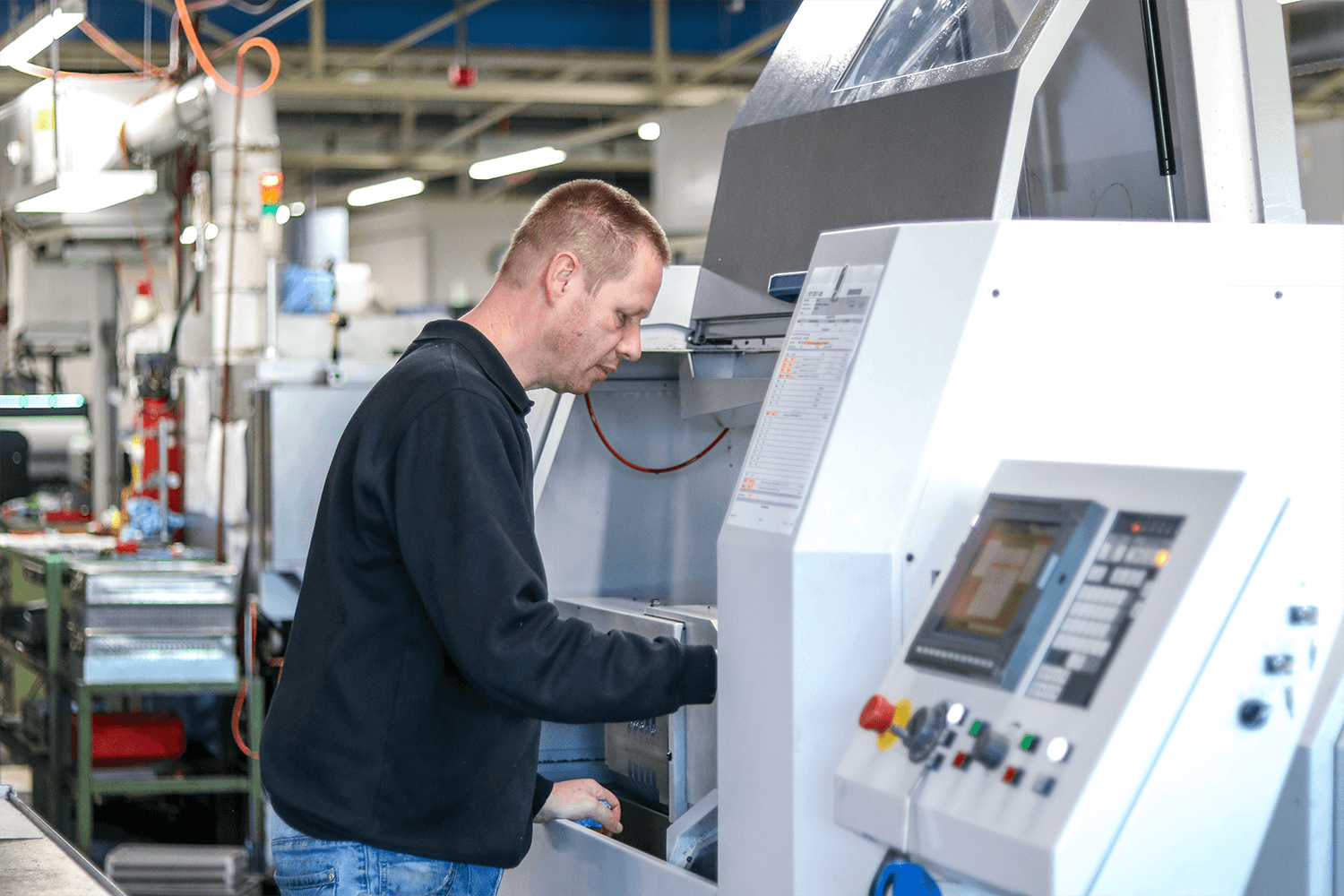

Swiss Turning and CNC Turning

Using Swiss turning and CNC lathes, HFI achieves precision machining of workpieces ranging from 0.3 mm to 150 mm in diameter. Multi-turret configurations of these machines allow for the creation of complex shapes. When combined with automatic bar feeders, robots, and cell configurations, we produce small to medium-sized series with very high precision and surface finish.

Laser Drilling

Through laser technology, holes with a minimum diameter of 0.02 mm can be drilled to a depth of 0.5 mm in virtually all materials.

CNC Milling

On our 3-axis and 5-axis machining centers, we can mill complex shapes with high precision and tight tolerances from a wide range of materials and almost all metal alloys. The products we mill are machined from raw materials with dimensions roughly equivalent to the size of a shoebox. This is achieved in small to medium-sized series with consistently high-quality results.

Orbital Welding

An advanced welding method that results in high-quality and consistent welds. Orbital welding creates seamless and strong connections with minimal distortion and risk of defects. It is an ideal method for critical applications where precision is of the utmost importance.

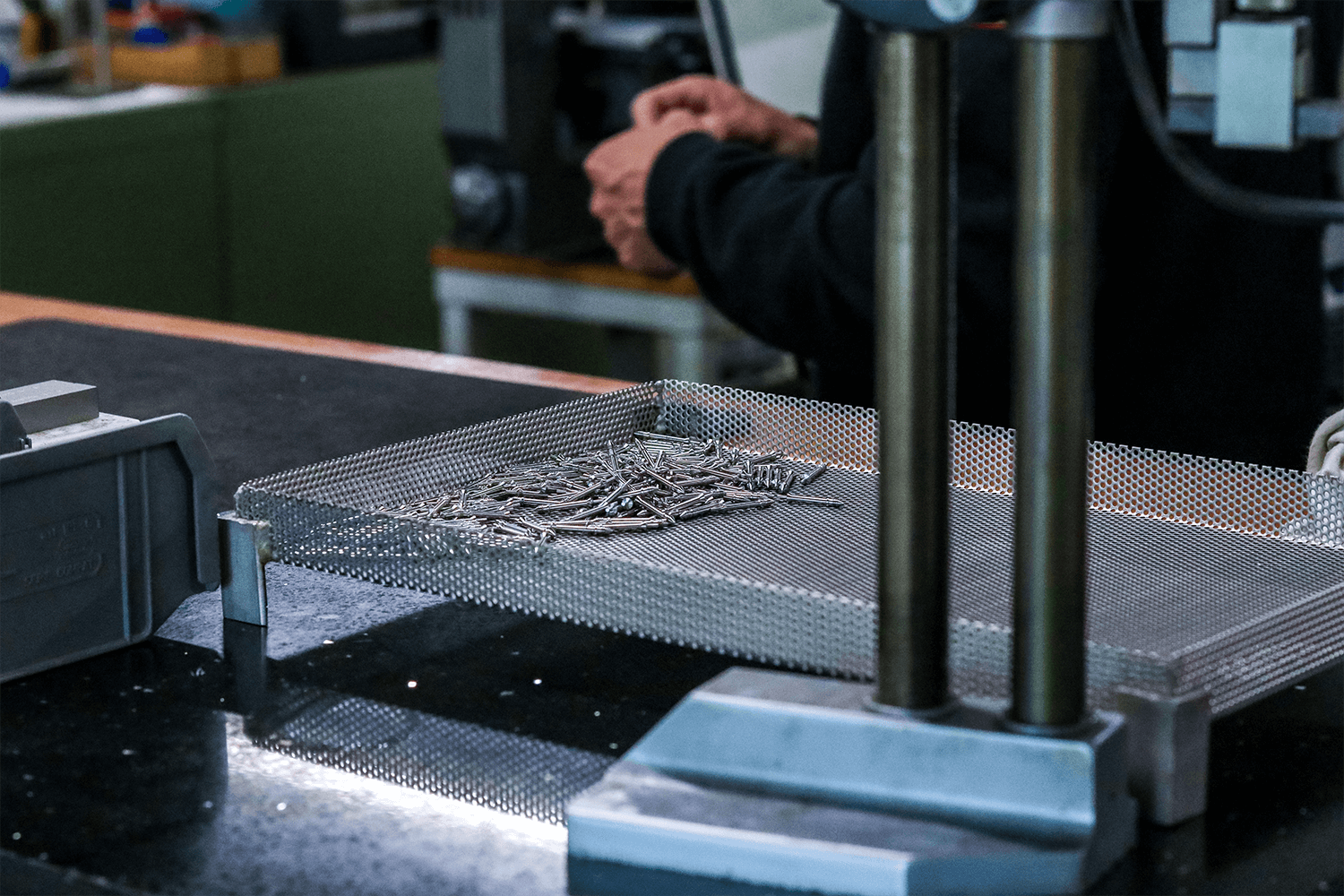

Finishing, Cleaning, and Assembly

In our specially equipped post-processing department, we ensure that each product is manually deburred, honed, or finished to perfection. Subsequently, the products are degreased and cleaned according to preferences and specifications (through ultrasonic cleaning, alcohol cleaning, or in an ECP bath [ElectroChemical Polishing]). Finally, any assembled products are manually and individually assembled and packaged.

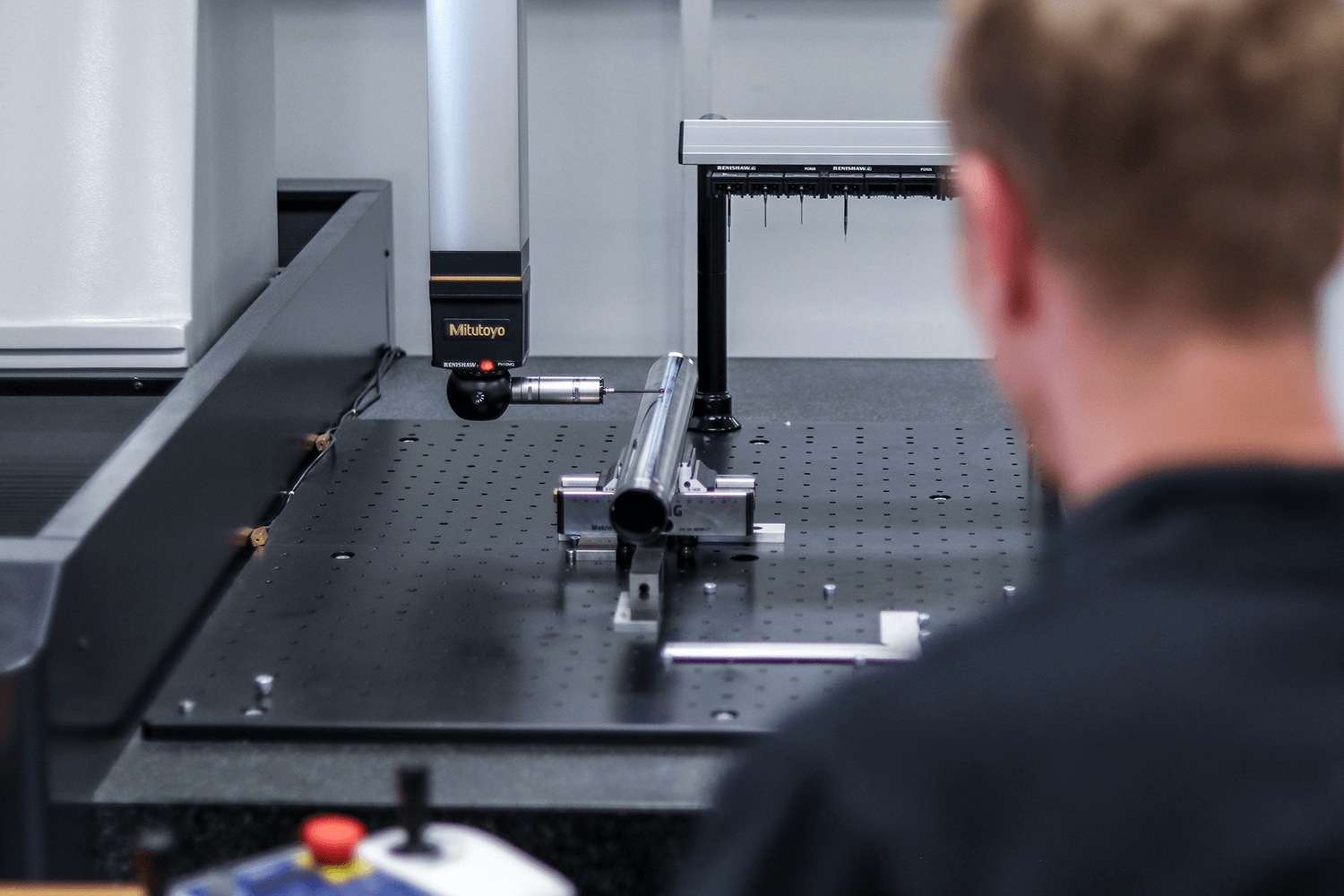

Quality Management

Quality is at the core of everything we do. It is in our DNA. The HFI quality management process includes continuous and rigorous inspection, traceability, and documentation to ensure that the products we deliver meet the highest standards and specifications. We dedicate ourselves to absolute excellence every day.